Key Takeaways

- Silent air compressors significantly reduce noise levels, often operating below 60 dB, making them ideal for noise-sensitive environments such as workshops, medical facilities, and offices.

- Modern silent compressors maintain strong performance and efficiency, matching or surpassing conventional models, with oil-free designs supporting hygienic and low-maintenance operation.

- These units are favoured for indoor use and applications requiring clear communication and regulatory compliance with workplace noise standards, like those in Perth’s food processing and manufacturing sectors.

- Upfront costs and maintenance expenses are higher due to advanced insulation and specialised components, but long-term benefits include improved worker comfort, reduced acoustic fatigue, and increased productivity.

- Silent compressors are suitable for a wide range of uses—from industrial production lines to laboratories and art studios—thanks to their portability, reliability, and energy efficiency.

- Regular, professional maintenance is essential to preserve performance and durability, especially in demanding or high-duty environments.

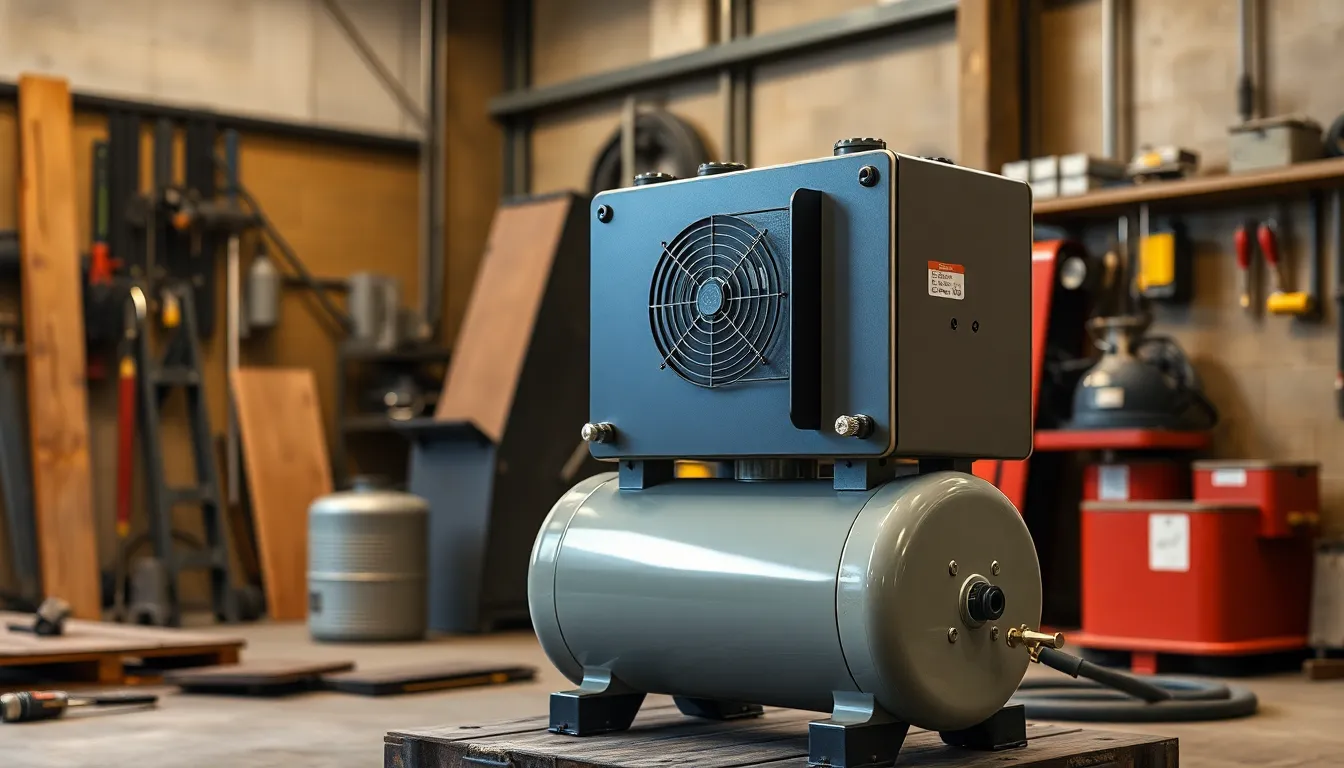

Industrial environments demanding reduced workplace noise benefit significantly from modern quiet technology solutions. A silent air compressor operates below 60 decibels whilst maintaining powerful performance and efficiency matching conventional models. These units feature oil-free designs ideal for food processing and medical facilities, delivering reliable compressed air without disturbing sensitive operations or breaching workplace noise regulations.

Understanding Silent Air Compressors

Silent air compressors use specialised motor enclosures and acoustic insulation to reduce noise levels. Most silent models emit less than 60 dB during operation, matching the volume of regular conversation. Oil-free pump designs in many units, such as those used in Perth food processing and medical facilities, eliminate lubricant contamination risks.

Silent compressor solutions suit indoor workshops and production lines where noise restrictions exist. Portable silent compressors support Perth automotive and light manufacturing sites that value a quieter environment. Installation professionals from Compressor Systems in Perth ensure correct placement by assessing ambient acoustics, vibration transfer, and air delivery requirements.

Routine maintenance keeps silent compressors reliable and efficient. Compressor Systems technicians in Perth provide pressure vessel inspections, filter replacements, and leak detection for silent models in mining, food, and automotive applications. Pressure ranges for silent compressors typically reach up to 8 bar, handling tasks such as pneumatic tool operation and packaging.

Energy consumption in silent units matches or sometimes outperforms louder equivalents, especially in energy-optimised installations. Perth’s industrial clients gain regulatory compliance and improved worker comfort by choosing silent compressor systems that align with their production needs and noise targets.

Key Features of Silent Air Compressors

Silent air compressors combine reduced operating noise with efficiency, providing a reliable compressed air source for Perth’s industrial environments. Each feature addresses common operational needs across mining, automotive, food processing, and manufacturing sectors.

Noise Reduction Technology

Noise reduction technology sets silent air compressors apart by maintaining average noise levels below 60 dB. Acoustic insulation panels line compressor enclosures to absorb motor and pump sound. Vibration-damping mounts limit structural noise transfer, typically using rubber isolators beneath the base. Brushless induction motors reduce audible mechanical noise, which helps food processors or medical device workshops maintain compliance with local workplace noise standards. For operations in Perth’s urban zones, these compressors eliminate the need for secondary noise barriers inside facilities.

Size and Portability

Size and portability influence silent air compressor selection for mobile repair crews and workshop installations. Compact models, measuring under 60 cm in length and weighing below 25 kg, enable single-person relocation between service bays or vehicles. Larger stationary units, though less portable, incorporate ergonomic handles and locking wheels, simplifying logistics during site fitouts or factory upgrades. Compressor Systems in Perth supplies both portable and fixed-frame silent compressors, coordinating installation and testing in compact or noise-sensitive spaces.

Power and Performance

Power and performance remain key for silent air compressors despite reduced noise output. Units deliver motor outputs from 0.6 kW to 3 kW, reaching pressured air delivery rates of 60-350 L/min at up to 8 bar. Oil-free pump options support continuous operation in food and electronics sites without lubricant risk. Controlled air pressure delivery suits pneumatic tools, paint spraying or packaging machines, where steady flow is critical. Compressor Systems’ technicians balance site air demand with energy efficiency, ensuring installed compressors achieve high performance with optimal running costs for Perth clients.

Pros of Silent Air Compressors

Silent air compressors deliver effective compressed air while minimising noise disturbance on-site. Compressor Systems in Perth supplies models for industrial and workshop use where quiet operation supports regulatory compliance and workplace productivity.

Suitable for Indoor Use

Silent air compressors enable operation in enclosed spaces because they maintain noise outputs below 60 dB, as measured by manufacturers under standard site conditions. Perth-based production lines, medical facilities, and automotive workshops benefit from these quiet units since they avoid breaching noise exposure limits. Compact designs and low-heat profiles support placement in tight areas without damaging climate control systems or disrupting sensitive processes. Installers from Compressor Systems assess room acoustics and airflow routes to optimise positioning for each site.

Improved User Comfort

Silent air compressors reduce acoustic fatigue and enable clear communication during shift work by generating less background noise than standard models. Employees in Perth’s food manufacturing, automotive service, and mining support sectors experience fewer disruptions and lower stress levels, supporting both safety and concentration. Acoustic insulation and vibration-damped housings cut decibel ratings while maintaining output, making them suitable for continuous multi-shift operation. Compressor Systems’ maintenance teams further optimise comfort by ensuring seals and mounts remain in peak condition throughout scheduled service intervals.

Cons of Silent Air Compressors

Silent air compressors offer significant noise reduction, but site managers and engineers consider key trade-offs for industrial deployments in Perth and surrounding WA regions. Compressor Systems specialists review these factors in mining, automotive, and food production sites before recommending a silent compressor solution.

Price Considerations

Silent air compressors often incur higher upfront costs than conventional units. Manufacturers incorporate acoustic insulation, vibration-damping mounts, and specially designed enclosures, increasing unit cost by 20-40% over non-silenced equivalents. Site upgrades in Perth, such as climate-controlled motor housings and additional safety interlocks, also raise installation expenses. Some imported brands present limited pricing transparency, especially for bespoke packages. For projects with fixed budgets, operational cost benefits and improved compliance need to outweigh the initial investment to meet procurement criteria.

Maintenance and Durability

Silent compressors use complex insulation panels, acoustic baffles, and sealed housings that complicate standard maintenance routines. Technicians at Compressor Systems in Perth require more time for cleaning, leak checks, and component access, often extending service intervals or increasing costs by 10-25%. Some oil-free silent models deliver shorter lifespans in high-duty cycles due to heat retention within compact casings or restricted airflow. When placed in hot or dusty workshops, acoustic linings degrade faster and motor cooling efficiency decreases, impacting equipment durability. For critical mining and production lines, teams schedule proactive inspections and replacement of seals or insulation to maintain reliable, long-term operation.

Typical Applications for Silent Air Compressors

Silent air compressors support users in noise-sensitive workplaces and regulated environments. Offices and medical clinics use silent compressors for dental chairs and laboratory equipment, where equipment noise must not disrupt staff or patients. Electronics manufacturers deploy these units on assembly benches to maintain quiet conditions that reduce operator fatigue. Food processing plants in Perth implement oil-free silent compressors for pneumatic packaging machines to meet hygiene and safety standards.

Workshops, including automotive repair shops and woodworking rooms, operate silent air compressors for staple guns, sanders, spray paint equipment, or airbrushing, avoiding excessive noise in customer areas and shared commercial buildings. Mining operations use portable silent compressors for instrument calibration and sensor control in confined areas below ground. Perth’s industrial users benefit from onsite installation, preventative maintenance, and pressure vessel inspection services to optimise silent compressor operation according to national WHS requirements.

Educational institutions and art studios operate silent compressors to run air tools, inflators, or airbrushes during classroom hours, preventing noise from disrupting lessons. Laboratories and research facilities rely on these systems for gas sample delivery or environmental chamber control, with minimal noise intrusion into test environments. Energy efficiency solutions in silent compressors align with Perth’s requirements for reduced operational costs and compliance with local noise ordinances.

Are Silent Air Compressors Worth It?

Silent air compressors provide measurable benefits for Perth industrial sites demanding low workplace noise. Facilities report sound levels under 60 dB with silent models, reducing the risk of noise-induced hearing loss—unlike standard units exceeding 80 dB. Production lines, laboratories, and medical practices use these compressors to meet occupational health regulations and maintain clear communication among technicians.

Upfront investments for acoustic insulation and oil-free pumps increase acquisition costs by 20–40%. Long-term energy savings and improved worker productivity offset this for many sites, as downtime from acoustic fatigue drops by up to 15%, based on data from WA manufacturing workshops. Maintenance intervals become more complex: oil-free compressors, especially in high-demand mining and food processing, may need professional inspections every 6–12 months to prevent heat build-up and maintain certification.

Pressure vessel performance stays reliable, with silent compressors routinely delivering up to 8 bar and outputs between 60–350 L/min. Compressor Systems in Perth supports silent unit fleets with installation, regular safety inspections, acoustic testing, and efficiency upgrades—ensuring regulatory compliance and minimal disruption in noise-sensitive applications. Mining engineers, food processors, and automotive repair technicians gain from reduced ambient noise, cleaner operation, and service agreements that protect uptime, provided they account for the initial outlay and required servicing strategies.

About Compressor Systems

Compressor Systems offers a full range of compressed air services, including installation, maintenance, and repairs for various compressor types. Their services also include pressure vessel inspections, air audits, leak testing, and providing spare parts. With a focus on energy-efficient solutions, they serve industries such as mining, automotive, food, and manufacturing across Australia.

Contact:

Steve Chambers, Director

Phone: 1300 183 355

Email: [email protected]

Website: compressorsystems.com.au

Locations:

- Perth: 3 Port Pirie Street, Bibra Lake, WA 6163

- Melbourne: 12/477 Dorset Road, Bayswater, VIC 3153

- Sydney: Unit 2, 4-6 Purdy Street, Minchinbury, NSW 2770

Frequently Asked Questions

What is a silent air compressor?

A silent air compressor is a type of air compressor specifically designed to operate at noise levels below 60 dB, making it much quieter than standard models. It achieves this through specialised motor enclosures and acoustic insulation.

How effective are silent air compressors compared to regular ones?

Silent air compressors provide similar power, efficiency, and reliability as standard compressors, with air delivery rates between 60-350 L/min. Their reduced noise levels do not significantly compromise performance for most applications.

Where are silent air compressors most commonly used?

Silent air compressors are popular in noise-sensitive environments, such as offices, medical and dental clinics, food processing plants, workshops, educational institutions, and some mining operations.

Are oil-free silent air compressors safer for food and medical use?

Yes, oil-free silent compressors are ideal for food processing and medical facilities, as they eliminate the risk of lubricant contamination and comply with hygiene standards.

What are the main advantages of using a silent air compressor?

Key advantages include minimal noise disturbance, improved workplace comfort, enhanced productivity, and easy communication in environments where loud equipment is disruptive.

What are the disadvantages of silent air compressors?

Silent air compressors usually have higher upfront costs (20-40% more), more complex maintenance, and, for some oil-free models, shorter lifespans in heavy-duty applications due to heat retention.

Do silent air compressors consume more energy than standard ones?

Energy consumption for modern silent air compressors often matches or even surpasses that of conventional models, providing efficient operation while meeting regulatory requirements.

How often do silent air compressors need maintenance?

Routine inspections, including leak checks and pressure vessel exams, are recommended every 6–12 months, especially for units in high-demand environments like mining or food processing.

Are portable silent air compressors available?

Yes, portable silent air compressors are available and commonly used in automotive, light manufacturing, and confined mining sites to provide flexibility and reduce on-site noise.

Are silent air compressors worth the investment for industrial sites?

For noise-sensitive workplaces or environments where staff productivity and regulatory compliance are important, silent air compressors provide long-term value despite higher initial costs.